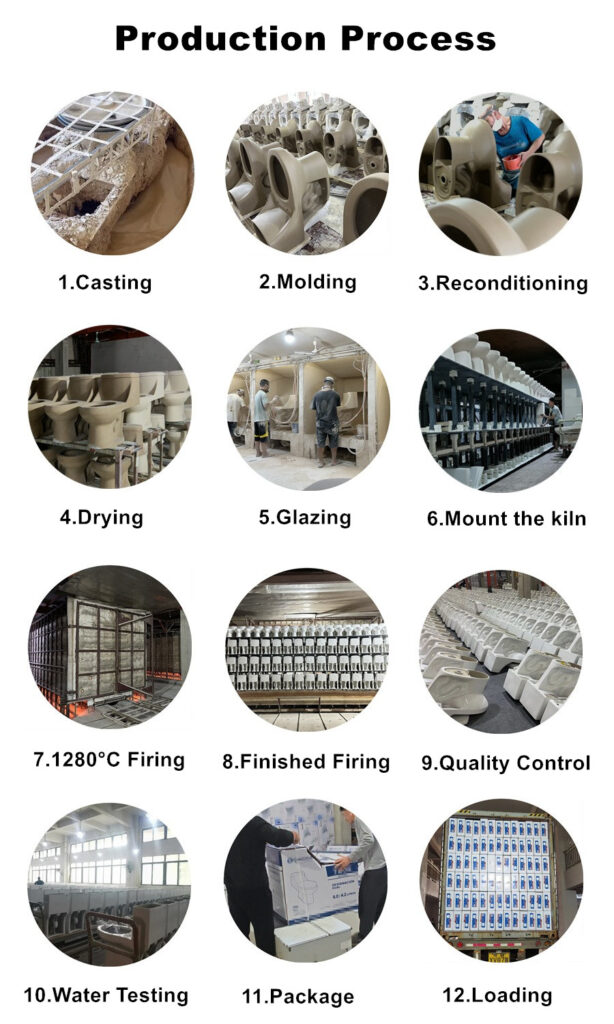

Manufacture Process

Ceramic Sanitary Ware Production Process

01

Raw Material Preparation

– High-quality clay, kaolin, feldspar, and quartz are carefully selected and mixed to form the base material.

02

Slip Making

The raw materials are ground and blended with water to create a fine slurry (slip) suitable for casting or molding.

03

Molding/Casting

The slip is poured into molds (for toilets, basins, etc.) or shaped by high-pressure casting to achieve precise forms.

04

Drying

The shaped products are dried in controlled conditions to remove excess moisture and prevent deformation.

05

Checking & Refining (Surface Smoothing)

After drying, each piece is inspected under oil or light to detect tiny cracks, pinholes, or uneven areas. Skilled workers then polish, trim, or repair the surface to ensure it is smooth and flawless before glazing.

06

Glazing

A smooth glaze is applied to the dried body, ensuring a glossy, stain-resistant, and easy-to-clean surface.

07

Firing

The glazed products are fired in kilns at around 1280°C, creating a strong, durable ceramic body.

08

Inspection

Each piece undergoes strict quality checks for surface finish, dimensions, and performance.

09

Assembly & Testing

For toilets, flushing mechanisms and seats are assembled; every product is water-tested to ensure no leakage.

10

Packaging

Finished products are carefully packed with protective materials, ready for shipment worldwide.

Pakage